Race & Ethnicity

Formulating opportunity for others for more than half a century

A love of chemistry is what connects desegregating lunch counters in 1960 to integrating cutting-edge technologies in 2020.

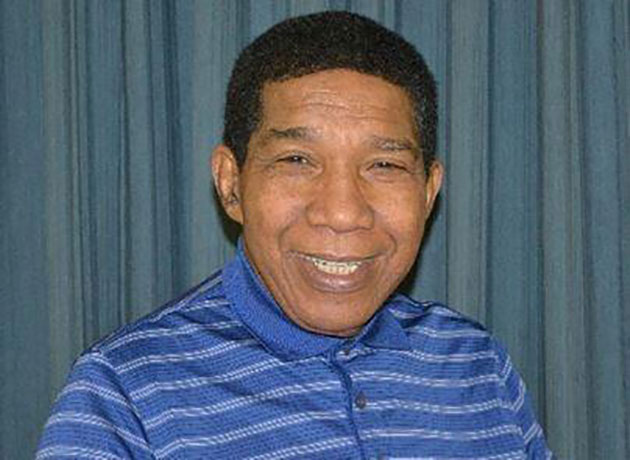

Oscar Johnson, a 25-year Boeing employee, is the chemical technology lead at the Boeing Guidance Repair Center in Heath, Ohio. This year, he was named the winner of a 2021 Black Engineer of the Year Award (BEYA), and in 2006, he was recognized for his participation in the 1960 Greensboro Sit-In by the International Civil Rights Center & Museum.

Oscar Johnson has spent more than two decades of his professional career focused on quality and safety as a chemical engineer. But his interest in chemistry first took root during a household chore: making soap.

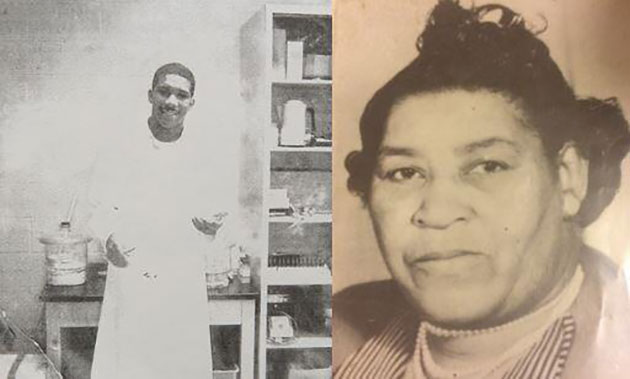

Growing up in Greensboro, North Carolina, Johnson was taught by his grandmother how to mix and heat cooking grease to create lye soap. Watching the chemical process unfold sparked a lifelong interest in chemical engineering — one that fueled him to join in protests during the Civil Rights Movement to ensure a career path for himself and fellow African Americans and, more than 50 years later, unveil cutting-edge technology that improved safety and quality in Boeing laboratories.

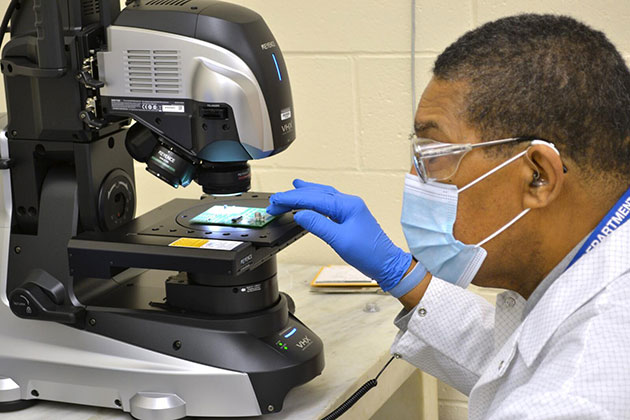

Johnson is a materials and process engineer and chemical technology lead at the Boeing Guidance Repair Center in Heath, Ohio. He tests chemical compounds, materials and processes used in the navigation systems of intercontinental ballistic missiles, nuclear-capable submarines and aircraft to determine their safety and suitability in extreme conditions. He also conducts the monthly safety inspections that have helped keep the labs injury-free for the past five years.

In 2016, he improved the site’s safety and technology capabilities even further by helping secure funding for and deploying new instrumentation in the labs. Prior to that, when Johnson and fellow teammates documented parts in need of repair, they were unable to identify the chemical composition that would reveal the root cause and had to ship the product or samples to other Boeing labs for analysis, adding to cost and customer response time.

Johnson had spent years studying the types of technology that Boeing labs would need to stay cutting-edge. After successfully proposing the need for mobile, adaptable instrumentation to his site director, Johnson implemented the equipment that engineers and chemists alike use to analyze, image and document chemical characterizations on-site; improve product quality; and introduce new capabilities like X-ray liquid analysis that other Boeing labs have since adopted.

Mike Ross photo

“I used to envy the labs in the TV show "CSI" quite a bit. Now, not so much,” Johnson said. “The new instrumentation gave us an immediate response to a problem that impacted engineers’ ability to timely solve issues, helping our internal and external customers and keeping the product quality high. I was thrilled to help. Being a contributor in my work today is something that goes back to my childhood — I was always looking for opportunities to be useful when my grandmother was rearing me.”

Chemistry in 1960

During his freshman year at North Carolina Agricultural & Technical State University, where Johnson later earned his master’s in chemistry, the Civil Rights

Movement was gaining momentum. Johnson realized he couldn’t concentrate solely on his studies.

“It was very challenging,” he said. “I realized I was learning in an environment that demanded I be engaged. I was constantly trying to make things better because, as one student put it, ‘Oscar, you get a degree, but where are you going to work?’ I wanted to make a better world for African Americans to live in by removing barriers.”

Johnson carried his chemistry books with him to sit-ins at the Woolworths lunch counter, joining in the historic Greensboro Sit-In to desegregate the five-and-dime store — a peaceful protest that catalyzed sit-ins across the country. After being arrested during protests and, later, in sit-ins at segregated theaters, Johnson learned his chemistry books offered a good distraction from the jail’s rough floors and helped him keep up on his studies.

Throughout his career, working as a chemist at various companies, including Dow Chemical — where he invented a special blend of polymers for labels on plastic bottles — and Boeing, Johnson has focused on community efforts to improve access and equity for others. He served on his city council as a racial equality liaison and engages with Heath’s Boeing Black Employees Association and Boeing Generation to Generation Business Resource Groups.

Mike Ross photo

“The BRGs have been a nice fit for me to reach out to others to make sure the pipeline is fueled with folks that could address the needs of The Boeing Company,” he said. “I try to be a window to what could be available to other students if they choose to be in STEM. For me, resilience has been about ensuring other people have opportunity.”

After 25 years at Boeing, Johnson is still motivated and enthusiastic about improving his workplace, his industry and his community.

“It’s challenging,” he said. “But one thing I’ve committed myself to is giving back because so many people gave back to me.”