From Subsonic to Supersonic, from Thermal to Acoustic

How well will your product slip through the air, insulate from noise, withstand acoustic vibrations, generate a sound, or propel a load? Find out at Boeing. Boeing works with you to tailor aero testing to your needs. Boeing’s wind tunnels produce subsonic to supersonic wind and subsonic thermal conditions in chambers of various sizes to confirm your designs. Acoustic chambers listen for a pin drop or match the volume and force of a jet engine. Bring your noise test to Boeing and you will hear the difference.

Nozzle, inlet, fuel, and hazard testing ensures that your propulsion system moves your customers to where they want to go. Boeing will help you get there. Boeing works for you.

Testing facilities include:

- Boeing Subsonic (low-speed) Wind Tunnel - BVWT

- Boeing Transonic Wind Tunnel – BTWT

- Polysonic (supersonic) Wind Tunnel – PSWT

- Icing wind tunnel – BRAIT

- Aero-acoustic Facility – LSAF

- Propulsion testing facilities

Boeing Vertical/Short Takeoff and Landing Wind Tunnel

The low-speed Boeing Vertical/Short Takeoff and Landing Wind Tunnel (BVWT), located in Philadelphia, has a large, versatile test section that is useful for testing fixed- and rotary-wing aircraft and non-aeronautical vehicles and structures. BVWT is a closed-circuit single-return tunnel and has a 20-by-20-foot, variable-configuration, test section. The tunnel is capable of speeds of hover to 0.3 Mach, with a dynamic pressure range of 0 to 160 pounds per square foot.

It includes a fully automated test-model positioning system and airspeed controller, state-of-the-art data collection and instrumentation, and stainless-steel honeycomb to improve flow quality. Touch-screen function control panels can display 30 monitored parameters. With the data updated every half second, these monitors provide for near-real-time display of multiple parameters.

The wind tunnel staff is experienced in all forms of force, pressure, flight control, vibratory, and dynamic testing of powered and unpowered fixed- and rotary-wing aircraft and other test articles in and out of ground effect.

Boeing Transonic Wind Tunnel

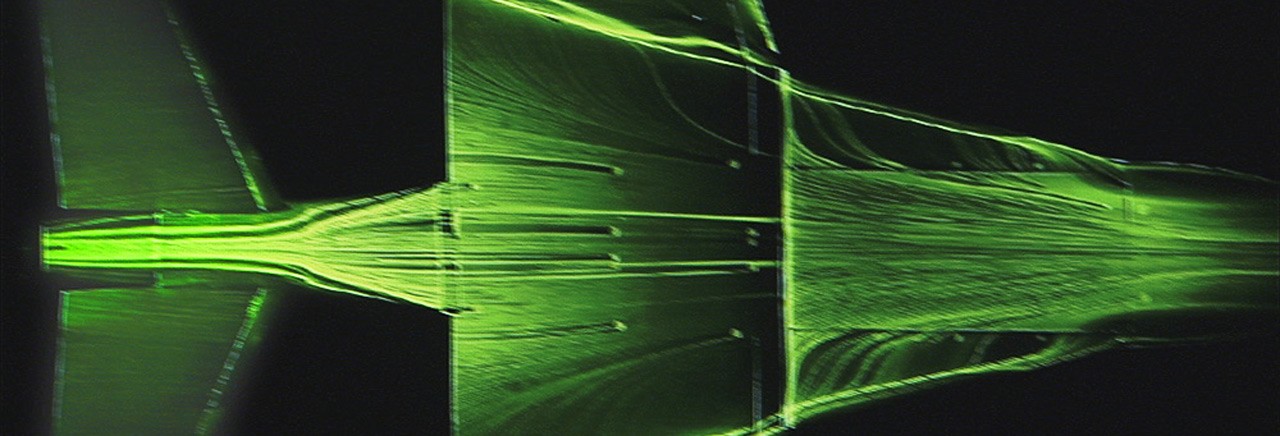

The Boeing Transonic Wind Tunnel (BTWT) delivers the best value for aerodynamic information to our customers in a safe, compliant, and secure environment, making it one of the best facilities in the world.

The BTWT is a continuous-flow tunnel with a Mach range of Mach 0.3 up to Mach 1.1. It has an 8- by 12-foot test section with 2-foot corner fillets; a dynamic pressure range from 0 to 840 pound/feet; controllable stagnation temperature and dew point; sting, swept strut, plate, and floor mountings; internal and external balances; electronic pressure scanning (EPS) up to 1,536 ports; and an inventory of EPS modules of appropriate load capacity and qualitative and quantitative flow imaging tools. An airflow facility is available for calibrating ducts and flow-through and powered nacelles.

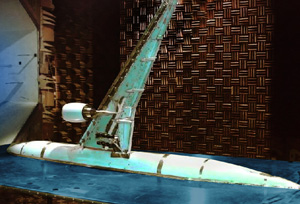

Polysonic Wind Tunnel

The Polysonic Wind Tunnel (PSWT) is an integral part of new product development at Boeing. It can generate scale-model inlet and aerodynamic data in the subsonic, transonic, and supersonic regime at various altitudes. It has two 4-foot-by-4-foot test sections, one for supersonic and one for transonic and subsonic testing, and a new gas turbine compressor with double the pump rate of the previous compressor.

Applications include basic flow visualization, two-dimensional contour plotting, and pressure mapping onto three-dimensional surface grids. Continuous shadowgraph systems, ultraviolet and oil flow equipment, and full photographic and closed-circuit television is available for all types of tests. A large family of primary model balances, miniature store balances, and some specialized balances are available for almost any model application. Many ranges and types of conventional and ultra miniature pressure transducers are available, and specialized equipment—including dynamic analyzers and videotape—can sense, record, and analyze results.

Boeing Research Aero-Icing Tunnel

The Boeing Research Aero-Icing Tunnel allows for aerodynamic testing of deicing systems on the ground, saving you considerable time and resources over in-flight testing.

The test section is configured to enable extensive visual investigations in either the icing or the aerodynamics mode. The facility also has a spray-bar system that generates supercooled droplets upstream of the test section to create cloud simulations. Also available is heated auxiliary air to the test section and test article.

It also is possible to determine performance and calibrations under icing conditions and the effectiveness of anti-icing and deicing systems. Ice shape molds can be made from ice formations built up on the test articles. Articles that can be tested include aircraft component sections, rotor-blade sections, and engine inlets and probes.

Low-Speed Aero acoustic Facility

The Low-Speed Aero acoustic Facility (LSAF) is powered by a 10,000–horsepower fan-drive system, sending airflow past silencers, through a settling chamber, and into our large anechoic chamber. The effect is a noise floor that is at least 10 decibels lower at most frequencies than any other wind tunnel in the world. With the low background noise levels, you can acquire data uncontaminated by competing background noise sources. The anechoic chamber can also be used for experiments that require low ambient noise and a free-field environment.

The LSAF is suitable for scale-model testing and for measuring noise and performance of aircraft model propulsion simulators, powered nacelles, airframes, and other components. The facility also offers jet-airframe interaction testing and other special techniques. You can simultaneously conduct noise and performance testing, and our advanced six-component balance can measure forces of up to 6,000 pounds with an accuracy of 0.1 percent. Our scanning equipment and near-real-time information-handling system allows for run models with 400 channels of pressure and temperature instrumentation.

Propulsion Laboratory

Boeing’s Nozzle Test Facility comprises two test cells, which are ventilated to maintain sea level atmospheric pressure. Each has a collector at one end to remove model exhaust with minimal noise intrusion into the surrounding community.

The 9-foot by 9-foot Propulsion Wind Tunnel is a non-return, induction-type facility that is set up primarily for inlet and aerodynamic testing, but it is easily adapted to other uses. It has extensive photographic and video equipment for monitoring and recording model configuration, flow visualization, test operations, and safety.

The Fuel Properties Laboratory offers fuel properties analysis to determine the net heat of combustion, thermal oxidation stability, vapor pressure, viscosity, density, lubricity, water content, dissolved gas content, and cold flow characteristics.

The four cells at the Fire and Hazardous Testing Laboratory accommodate flame, puncture, and explosion testing, including fire testing that requires backside cooling, preheat, or vibration conditions. They also be used to evaluate fire detection and extinguishing systems and the ignitability and flame propagation of liquid fuels and materials.

Request more information from Boeing Testing Services

Contact Boeing Testing Services via e-mail at bts@boeing.com.

Current Boeing airplane customers: Are you a current owner or operator of a Boeing-delivered airplane seeking maintenance repair or overhaul services, maintenance documents, engineering drawings, spare parts, or resolution of in-service issues? See MyBoeingFleet.com for direct personalized access to information essential to the operation of Boeing-delivered aircraft.